Digital Feature: The Need to Go Beyond the Digital Twin

T. GOFF, Hexagon, Huntsville, Alabama

Owner operators, as well as engineering firms, continue to face historic challenges in implementing projects. These challenges are coming with more pressure from stakeholders to ensure the projects are delivered on schedule, within budget, and with limited resources. The complexities in project execution increase as projects grow larger. Likewise, the need to efficiently package work to meet schedules and budgets is paramount in reducing downtime as capital expenditures on existing facilities increase.

For many years now, the “Digital Twin” approach has been growing and getting us one step closer to addressing these challenges. In 2013, International Data Corporation (IDC) predicted that the digital universe would grow by a factor of 10, from 4.4 zettabytes (ZB) in 2013 to 44ZB in 2020. Again, in 2018, IDC predicted that the digital universe would grow to 175ZB by 2025! And in 2019, Gartner defined the Digital Twin as “a software design pattern that represents a physical object with the objective of understanding the asset’s state, responding to changes, improving business operations and adding value.” It has been proven over and over that quick access to the most up-to-date information in a Digital Twin enables better decisions, improved business processes, enhanced productivity and the reduction of operational risk.

The Smart Digital Reality. But is building a Digital Twin enough to meet the challenges and manage all this data? To move beyond the “Digital Twin” and to the next level of global industrial assets data management, Hexagon introduces the digital and data-driven Smart Digital Reality™, enabling customers to globally leverage data throughout their asset’s lifecycle. This new level of digital reality manages data from conceptual design to decommissioning transforming industrial facilities into lean, efficient and safe operations that improve the bottom line while assuring a sustainable future. This digital leap forward fuses the physical world with the digital world in real time. It's not just a virtual representation of a physical asset. The Smart Digital Reality is infused with intelligence to automate processes and analytics to increasingly remove human intervention on the journey to a fully autonomous future.

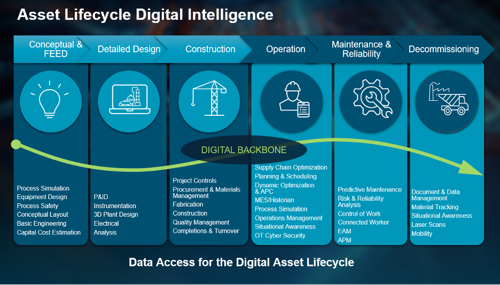

Whether during new facility construction or existing facility operations, data is captured and processed via Hexagon’s proprietary Digital Backbone. Context is added by layering 1D documents, specifications and 2D schematics over 3D models, regardless of the source, due to Hexagon’s proprietary Digital Backbone solution being source and vendor agnostic.

The result enhances execution of work processes that run natively within this highly intuitive environment allowing consumers to generate new insights about the asset in support of faster, more accurate decisions and actions that lead to improvements in safety, quality, efficiency and productivity. All of which contribute to economic and environmental sustainability.

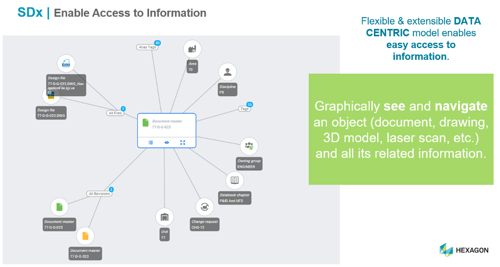

Single Version of Truth. To help companies achieve these Digital Reality benefits, Hexagon provides enterprise solutions for different phases of an asset’s lifecycle. The Smart Digital Reality is the backbone that connects these enterprise solutions and their data on one platform enabling a trusted “single version of the truth.” The outcome is a Smart Digital Reality that is far superior to any digital twin. At the heart of the Smart Digital Reality today is Hexagon’s SDx technology. SDx provides a modular, cloud-based data-centric solution empowering our customers to design, plan, build, operate and maintain these critical assets more efficiently, more profitably, more securely and more sustainably.

Digital Maturity. Owners in the manufacturing and process industries as well as EPCs are at various stages of digital maturity. Hexagon understands this and is providing Digital Reality solutions for all digital maturity stages across the asset lifecycle. To prevent barriers to adoption, the Digital Reality can be implemented gradually using Hexagon solutions in different stages. The extent of Digital Reality maturity required is based on the level of digitalization already in place at an organization.

For example, a company could start its digitalization journey with a brownfield (existing) facility where it has structured and unstructured data and documents that define the facility configuration. These facilities usually have paper-based documents that have no intelligence for digital navigation. Smartifying these documents and building data relationships automatically could save users up to 30% of their time searching for information. For companies near the beginning of their digital transformation journey, this is an excellent start, empowering better decision-making from more intelligent data. Or, a company could start its digitalization journey with a project using the Hexagon Smart suite of design tools and SDx as the collaboration platform that manages all the project data and correspondence between the client, contractors and vendors and simplifies the handover process to operations. Or, your company may be mature in its digital journey with having intelligent 2D schematics, 3D models and even laser scans and you need a platform to bring all the data together for intuitive viewing, navigation and decision-making. No matter where you find yourself along your digital transformation journey, Hexagon can help you achieve your next-level goals.

Overall, the goal of Hexagon’s Smart Digital Reality is to increase asset efficiency and offer a digital representation of current and historic plant configurations along with related performance information. Informed, data-driven decision-making becomes the norm, and the easy sharing of Digital data with multiple departments, contractors, vendors, and stakeholders, increases collaboration and reduces operational risk. Hexagon’s solutions help people design, engineer, construct, operate and maintain industrial assets as well as build and maintain a digital ecosystem throughout the asset’s lifecycle allowing for a continuous journey of operational excellence.

In this Going Beyond the Digital Twin with Smart Digital Reality blog series, we cover three foundational aspects of true digital transformation. We start with data and document management in the next blog to address both structured and unstructured data challenges for industrial assets. The third blog covers the Smart Digital Reality in Project Execution and the final one covers the Smart Digital Reality in Operational Assets.

If you found this article useful, continue reading the next one covering Data and Document Management.

About the author

Tom Goff is a Senior Industry Consultant with Hexagon’s Asset Lifecycle Intelligence division with more than 30 years of experience across multiple industries (Oil & Gas, Chemical and Nuclear) in engineering, construction, project management and information management, and has also led operational excellence initiatives. As a Senior Industry Consultant with Hexagon, Tom leads consulting initiatives with customers in their digital transformation journey. He has a bachelor’s degree and MBA from Capella University, is a certified PMP and LSS Black Belt, and a veteran of the U.S. Army.

Comments