Online Exclusive: Advanced hydrocracking unit flow scheme optimization and integration approach to maximize refinery margins for a residue upgrading project

V. Ramaseshan, S. Gajadhar, A. A. Ghabbani and H. A. Abdulal, Dhahran, Saudi Arabia; N. Tiwari, Honeywell UOP, Gurugram, Haryana, India; M. Balodia and M. Sangalli, Honeywell UOP, Des Plaines, Illinois; and S. Sood, Honeywell UOP, Summit, New Jersey

The integration of a solvent deasphalting (SDA) and hydrocracking upgrading complex provides a favorable techno-economic return for residue upgradation at relatively lower capital expenditures vs. other alternatives for a brownfield project. With a diminishing demand for high-sulfur fuel oil and the consequent reduction in market price, Saudi Aramco decided to upgrade bottom-of-the-barrel material to higher-valued products. This article outlines the efforts made by Saudi Aramco, along with its technology partner, in optimizing the residue upgrading section of the complex to maximize the overall return on investment (ROI) of the project. It also examines the various optimization and rationalization steps done with the technology provider through the development of the design of the units. The design being engineered ensures safety, operability and reliability, while leveraging the asset margins available within the existing refinery complex.

Background. Saudi Aramco operates a semi-conversion refinery at Ras Tanura (RTR) on the east coast of Saudi Arabia. Since its inception in the 1940s, RTR has gone through multiple phases of expansion and upgrades to meet the kingdom’s demand for transportation fuels and to generate value for Saudi Aramco’s downstream business. RTR has a nominal capacity of 550,000 bpd, processing a crude mixture of Arabian Extra Light (AXL), Arabia Light (AL), Arabian Heavy (AH) and Condensate (Khuff). The refinery has multiple conversion units, which include a naphtha hydrotreating (NHT) unit, reformers [both semi-regeneration (SR) and continuous regeneration (CCR)], a light naphtha isomerization unit (Isom) unit, a two-stage hydrocracking (VGO HCK) unit, a distillate hydrotreating (DHT) unit, a visbreaking unit (VBU), an asphalt oxidation unit and auxiliary processing units, such as multiple sulfur recovery blocks, mercaptan oxidation units, a hydrogen generation unit, and utilities and offsite units.

The refinery is a semi-conversion complex producing between 50,000 bpd–75,000 bpd of high-sulfur fuel oil. As fuel oil has limited marketability and consequently low value, the refinery economics are negatively impacted over the long run. Consequently, to improve the refinery’s profitability and to ensure robust economics going forward, the residue upgrading project (RUP) was conceived with the objective of upgrading the residue to optimal white oil products (distillates and naphtha) while meeting Saudi Arabia’s demand for asphalt.

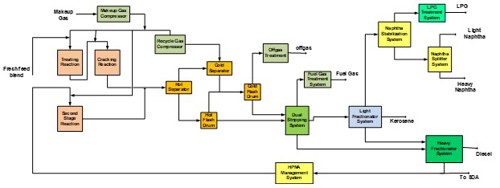

Multiple flow schemes involving hydrogen addition and carbon rejection were initially screened. However, based on the target product slate requirements (market demand, limitations in plot space, the existing refinery configuration and blending component availability), a SDA process with a fixed-bed, high-conversion hydrocracking flow scheme was chosen for the residue upgrade, which provides a higher net present value (NPV).

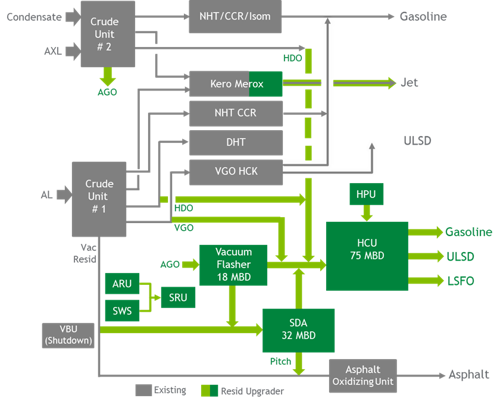

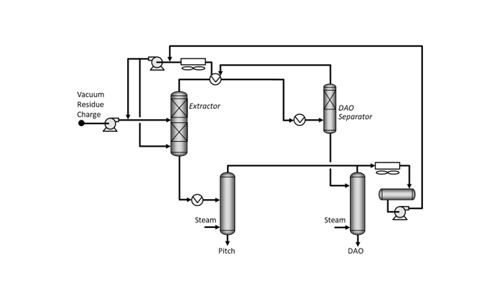

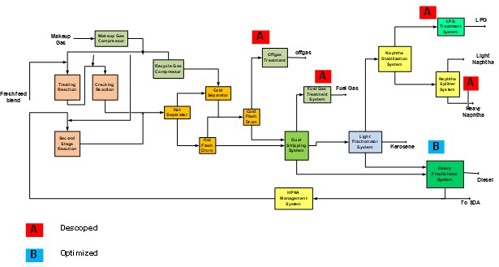

FIG. 1 provides the high-level flow scheme. TABLE 1 provides the current product slate and the expected product slate after RUP’s completion.

FIG. 1. The RTR’s RUP flow scheme.

TABLE 1. RTR’s production after RUP’s completion.

To ensure the targeted production rate for the refinery, the major conversion units for the RUP include:

- A 75,000-bpd advanced, two-stage hydrocracking unita (HCU) with a target conversion of > 97%

- A 32,000-bpd high-lift, two product-cut SDA unit

- A30,000-bpd kerosene treating unitb.

In addition to the conversion complex, additional auxiliary units such as a hydrogen production unit (HPU) with a sulfur recovery block have been proposed.

The feed being processed in the refinery is a mix of Arabian crudes (AL, AH, AXL and Khuff condensate). Based on the targeted product slate, the optimized crude diet was initially considered a mix of AL, AXL and Khuff condensate.

Based on the crude slate, it was necessary to upgrade the available vacuum residue (VR), atmospheric gasoil (AGO), excess vacuum gasoil (VGO) and distillate range material within the refinery. As the objective of the project was to minimize fuel oil while meeting asphalt demand, it was imperative that the SDA unit chosen was operated at high lift [high deasphalted oil (DAO) yield]. The lift needed to be optimized considering the quality of the pitch produced in the SDA unit to be blended with VR to make asphalt, while simultaneously the DAO quality was not compromised to be processed within an HCU.

Moreover, the limitation imposed by the overall asphaltene level in a feed to a hydrocracking unit would necessitate fractionation of the bottoms from the condensate processing section (when processing a mix of condensate and crude). The mix properties of the intermediates formed (DAO, excess VGO, distillate) must be such that it can be processed in a high-conversion HCU with the objective of maximizing distillate products and minimizing bleed. A closed-couple operation of the HCU with the SDA unit would thus be necessary.

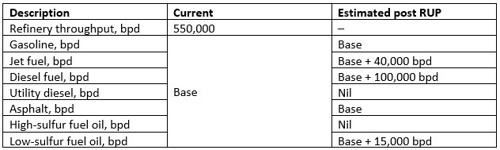

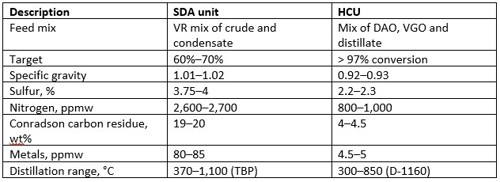

Based on the above, the feed qualities optimized for the SDA unit and the HCU were developed and are provided in TABLE 2.

TABLE 2. Feed definition

Conversion complex (SDA-HCU). The heavy crude characteristics that distinguish them from conventional crudes includes unusually high concentrations of contaminants such as nitrogen, sulfur, Conradson carbon residue and metals. The concentration of sulfur, nitrogen and Conradson carbon residue in the VGO fraction increases as the crude becomes heavier and requires a careful selection of a graded-bed catalyst system to protect active catalysts in the unit. The complexity of the composition of these materials creates new challenges for catalyst and process design.

Relying on bulk properties of the feed was not sufficient, and understanding of the composition at the molecular level became necessary. Characteristics of the molecules indicated that the crude sources could have a significantly different response in terms of cracking activity and selectivity to distillate yields. Accordingly, a new degree of sophistication and understanding must be applied to the design of the effective catalytic functionalities and selection of the optimum catalyst and process configuration. These highly aromatic and difficult feedstocks require a high-severity operation of hydrocracking that results in undesirable aromatic ring condensation reactions that generate heavy polynuclear aromatic (HPNA) molecules. Since these HPNAs are precursors to coking and catalyst deactivation, the understanding of HPNA formation and management becomes an important consideration in the catalyst loading and unit design.

A few of the key challenges faced by refiners is to understand the right lift of DAO in the SDA unit and the percentage of DAO that could be introduced to the HC feed blend before facing an unmanageable load of contaminants and conversion challenges in the HCU. The co-authors’ company has an extensive database of DAO, based on different crude sources. However, an understanding of DAO at the molecular level from the specific feed sources becomes important in the proper design of the catalyst system.

Based on the unit objectives and challenges in processing this heavier feedstock, the co-authors’ company offered an optimized and complete solution based on fully integrating the SDA unit and the HCU. The co-authors’ company has an outstanding level of commercial experience in hydrocracking heavy feedstocks and extensive development work to address the demand for deeper bottom-of-the-barrel conversion to clean fuels. In addition, the company has leveraged various research programs conducted in the past to evaluate processing DAO and VGO blends over a select group of proprietary hydrocracking catalystc to design the originally proposed system which was further optimized based on pilot plant studies specifically conducted with Saudi Aramco’s feed.

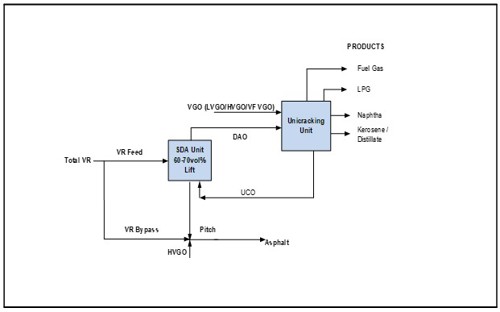

SDA. Based on the desired objective, the co-authors’ company proposed a two-product design SDA unit with a super-critical DAO separation section. The lift across the DAO was optimized between the 60%–70% range to meet the overall product qualities. An integral vacuum flasher was provided within the SDA unit to reject the heavy ends from the condensate bottoms, which was then mixed with conventional VR and processed. The solvent used was refinery available butane. The pitch produced was then blended off with excess VR, along with excess HVGO, if necessary, to produce an asphalt meeting 60–70 penetration. FIG. 2 provides a typical layout of the SDA unit.

FIG. 2. Typical flow scheme of a SDA unit.

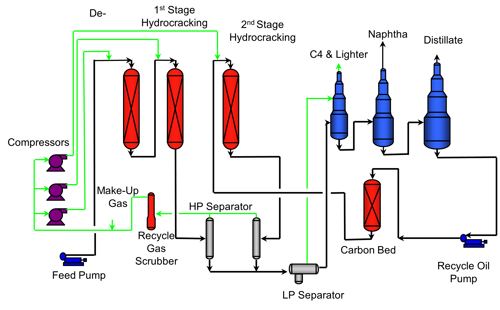

An advanced HCUa process. Based on the desired objectives, the co-authors’ company proposed an enhanced two-stage HCUa configuration, along with integrated recycling to process the unconverted oil (UCO) purge in the vacuum flasher and SDA unit, thereby targeting maximum conversion.

FIG. 3. Flow scheme of the advanced HCUa.

The co-authors’ company’s long-term DAO hydrocracking commercial experience is further enhanced by the expertise in proprietary SDA technology which allows for the optimization of the SDA unit and HCUa to provide an integrated technical solution for the overall complex rather than individually optimized units.

The synergy between the unit provided Saudi Aramco with an optimized solution for the desired complex product yields and unit integration for this refinery’s expansion project.

The configuration was strongly influenced by the optimization of the vacuum flasher, SDA unit and HCU. Key elements that influenced the outcome of the configuration were:

- The metals content of the VR and its distribution in DAO/pitch. This had a big impact on the quantity of de-metallization catalyst necessary for a 30-mos cycle length. The estimation of metals distribution was key to an appropriately sized metal guard bed for a sustained 30 mos of operation between turnarounds. Higher lift of the DAO improved the complex yields. However, higher lift requires increasing catalyst volume for the same cycle length due to increased contaminants and catalyst inhibition.

- The DAO feed had heavier molecules, including polyaromatics, so deep hydrotreating was important to increase denitrification and aromatic saturation from the pretreat catalyst.

- The cracking of DAO molecules with a higher carbon number than VGO was challenging and was expected to require more cracks per pass than a typical VGO feed. For example, the higher boiling DAO molecules are substantially cracked into VGO boiling range molecules in the first stage. UCO with the DAO reduced boiling point molecules are cracked further into distillate range molecules in the second stage. Accordingly, the activity and volume selection of the hydrocracking catalysts in both stages must consider this aspect of the feed.

The proposed solution optimized feed quality, the product cut point and UCO recycling through the SDA unit, which thus maximized overall conversion. In generating this solution, the co-authors’ company leveraged the breadth of its bottom-of-the-barrel technology portfolio and the depth of process expertise to develop a customized unit design to maximize distillate production and overall conversion from the complex (FIG. 4).

FIG. 4. Flow scheme of the optimized conversion SDA-HCK complex.

Pilot plant program. The co-authors’ company continues to invest significantly in research and development. A key part is the company’s pilot plants that are used to demonstrate technologies and catalyst offerings. As a risk mitigation strategy from Saudi Aramco’s perspective, extensive pilot plant testing was a critical part of the overall technology offering to showcase the accuracy it. The optimization between the two units, as well as individual units, was a key focus of the pilot plant studies.

SDA unit pilot plant program. One pilot plant test for the SDA unit was designed to verify and quantify the ability of the SDA unit to produce both DAO and bitumen. The primary focus of this SDA pilot plant study was to quantify, in real terms, the correct lift within the SDA unit that was able to produce a DAO and a pitch stream which could be disposed as feed to the HCU and as bitumen blending stock. It was targeted to generate DAO with different lifts to enable optimization between the DAO and HCUs. The hydrocracking testing was also essential to optimize the hydrocracking flow scheme and conversion levels to ensure stable operations. The pitch generated from the SDA pilot plant was targeted to be blended with excess vacuum tower bottoms and/or VGO to produce asphalt (bitumen).

The SDA pilot plant program was executed with the following steps:

- A full-fledged SDA program was conducted using the co-authors’ company’s continuous SDA pilot unit testing in its laboratories.

- The SDA plant was configured to produce two products, DAO and pitch. The feed to the SDA plant was vacuum tower bottoms material, with specifications close to those expected to be operated at the RTR complex.

- Cutter components for the pitch to produce bitumen were based on the feedstock material sent. The pilot plant facility generated a blending framework to estimate the potential preliminary blends using SDA pitch, VTB and VGO (HVGO) to produce a 60 grade–70 grade bitumen (asphalt). With the blends produced, testing was conducted to confirm all the properties of paving asphalt. The results of the tests confirmed DAO quality and formulations to produce 60-grade–70-grade asphalt with the SDA pitch.

HCU pilot plant program. A full-fledged pilot plant study was conducted for a two-stage HCU to verify the catalyst activity, yields and product quality, using a blend of DAO derived from the SDA run and the VGO supplied. With heavy feed processing and recycle mode operations, the propensity to form HPNAs in the recycle oil streams is high. HPNA has detrimental effects both on the catalyst and with respect to fouling within the unit. For this, a sophisticated and integrated two-stage pilot plant was used to simulate the actual commercial operation. The HPNA chamber was also simulated in this integrated pilot plant to understand the HPNA formation with this kind of feed. Additionally, unit optimization was performed utilizing the following parameters:

- Combined feed ratio (CFR) optimization: CFR optimization was performed to maximize distillate yields, while maintaining the conversion between the two stages to meet the product quality requirements.

- Optimization between pretreat and cracking catalysts: With this kind of feed, graded bed and demetalization catalyst were a critical requirement. Conradson carbon reduction was monitored across a proposed graded-bed system and loading was optimized accordingly.

- Conversion optimization between the first and second stages: This was an important evaluation from this pilot plant. Based on the product in feed, there was an optimum conversion determined for each stage to maximize the distillate yield.

- Conversion cut-point optimization and optimization between different cuts: Considering a heavier feed, there was a scope to optimize the cut-point between diesel and UCO while still meeting the distillate distillation specifications. With the heavier feed, the separation between diesel and UCO was relatively easier, and there was a proprietary SDA process to optimize the cut-point between diesel and UCO products. In addition, the selection of the latest-generation hydrocracking catalystsc for both stages still provided the required cold flow properties while optimizing the recycle cut point.

- Catalyst optimization: Catalyst loading optimization on both on the pretreat and hydrocracking catalysts was an important outcome of the pilot plant study. The pilot plant was originally loaded with the co-authors’ company’s previous-generation catalyst system. Based on further optimization, the authors’ company used the latest generation catalysts HC-740 and HC-730 as an optimized loading.

The metal systems on these 700 series hydrocracking catalysts have been improved, along with the use of state-of-the-art high activity components in the base vs. previous generation catalysts to achieve optimum interactions between the active metals and catalyst support. The combination of these high-performance raw materials led to an unprecedented step forward in increasing activity without loss of selectivity. The HC-740LT catalyst enables:

- High selectivity and activity: Increased yield of distillates with improved activity

- High volume swell: Increased volume yield and higher hydrocracker margins

- Premium distillate quality: Improved diesel cetane and cold flow properties

- Processing difficult feeds with increased cycle length or lower catalyst volume vs. previous generation catalysts.

This entire pilot plant program was conducted utilizing the feed supplied by Saudi Aramco, comprising of VR and VGO. Some of the key features of the pilot plant used for this Saudi Aramco study were the following:

- Internally producing the DAO from the VR in the pilot plant simulating the commercial SDA unit.

- Use of an integrated two-stage hydrocracking pilot plant at the co-authors’ company’s Riverside facility to match commercial unit performance for operating conditions, product yields and product qualities. No scale-up factors were required.

- Simulation of the second stage environment, specifically the ammonia environment. The second stage catalyst activity and yield are very sensitive to ammonia and is an important requirement to simulate this environment.

- Simulation of commercial fractionation to gain a better understanding of the yields and product properties. Cut-points in the vacuum column were studied and optimized to maximize the distillate yields while meeting product specifications.

- Two pilot plants were combined to simulate HPNA carbon bed chambers to gain a better understanding of HPNA formation when processing a heavier feed like DAO, and its impact on the catalyst system.

During the pilot plant study conducted in a year-long program, various optimization steps were performed to select an optimized configuration and catalyst system for this major investment. TABLE 3 provides a summary of the results of the pilot plant testing, and FIG. 5 details the pilot plant’s set up.

FIG. 5. HCU pilot plant testing flow scheme.

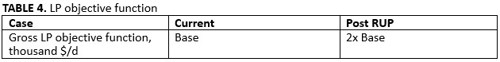

Complex design and implications. Based on FIG. 5’s flow scheme, the overall refinery LP modeling was conducted, and TABLE 4 provides a comparison between the current refinery (Base) and post RUP.

On completion of the design, a detailed cost estimate was developed. Though the project economics were very favorable, the overall CAPEX on the complex had risen significantly above the initial budget. The increase in CAPEX was primarily on account of:

- Engineering requirements

- Scope addition

- General escalation (inflation).

Therefore, the project development team decided that further optimization was necessary to ensure a lower CAPEX (in line with management expectations) while ensuring high returns and meeting market demand. Consequently, a detailed exercise involving optimization and scope rationalization was carried out.

Configuration optimization. While maintaining the same overall flow scheme, another review on the feed processing mix within the complex was carried out. As per the original scheme, the residue from the condensate section required further processing in a vacuum flasher within the SDA unit to ensure minimum asphaltene carry over to the HCU. An optimization of feed being processed in the condensate unit was carried out by Saudi Aramco which allowed for co-mixing of condensate bottom with DAO, excess VGO and distillate, while still meeting the asphaltene limitations imposed within the HCU. Furthermore, by readjusting the distillate mix processing within the existing facility and withdrawing kerosene as a product from the HCU, optimization across the KTU was feasible.

Consequently, the vacuum flasher section and the KTU were descoped. Since the feed quality to the SDA unit had marginally changed, a lift across the optimized SDA unit (to meet the asphalt requirement) was conducted. The SDA unit lift was still maintained between 60%–70%. The feed quality into the HCU (in terms of impurities) was maintained within the design limits and the overall flowrate sustained at 75,000 bpd.

With the feed optimized, a consequent rationalization and capacity optimization across the HPU, SRU complex and offsites was achieved.

With these tasks completed, Saudi Aramco initiated a complete optimization of the hydrocracking equipment and flow scheme. The objectives of this exercise were the following:

- The optimization of the main fractionation column scheme within the HCU. A tradeoff between distillate yield vs. the fractionation system was employed—e.g., a single main fractionation column as opposed to a dual product fractionation column.1

- The ability to optimize the light-end section of the new HCU by making use of available light-end fractionation capacity within the refinery, while maintaining the ability to produce stabilized products from the new HCU.

- Conversion optimization on account of the use of the HPNA adsorption system utilized within the HCU to maximize conversion.2

- Optimization of equipment margin requirements within the design.

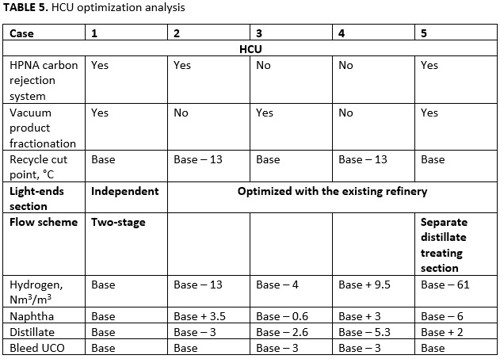

A detailed analysis was conducted based on the same factors, while ensuring that the optimal energy efficiency brought forth in the HCU design—on account of the dual-stripping column design—was maintained, as energy efficiency is paramount in any bottoms upgrading scheme. FIG. 6 provides a review of the optimization exercise across the HCU.

FIG. 6. Advanced HCUa flow scheme optimization.

Dual stripper solution to improve energy efficiency and reduce CO2 emissions. As previously explained in detail,1 the co-authors’ company has designed several new HCUs with a dual-stripper flow scheme, and several of these have been put into operation, making this a commercially proven solution. By implementing this flow scheme, refiners will be able to reduce the product fractionator feed heater duty by ~20% vs. a single-stripper flow scheme, depending upon the conversion of the hydrocracking unit.1 Several HCUs have been designed and are currently operating with this scheme.

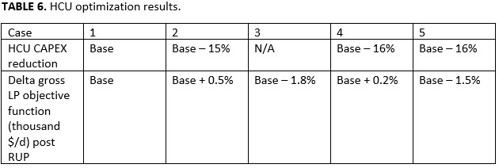

A tabular analysis of the HCU optimization is shown in TABLE 5. It should be noted that Case 1 is the Base design for the HCU, and the various options around the optimization across the HCU are highlighted as various cases. An alternate flow scheme of a staged hydroprocessing unit was also considered, where the distillate portion was hydrotreated at a lower pressure and coupled with the HCU section. The primary driving force was to look at possible CAPEX reductions on account of lower capacities in the high-pressure loop of the HCU.

The corresponding result on CAPEX savings and resulting LP gross margins are shown in TABLE 6.

TABLE 6. HCU optimization results.

Economic optimization results. Based on the above, it can be inferred that option two (the two-stage HCU with a single product fractionation column but with a dual-stripping section) and optimization of the light section provides the maximum overall CAPEX reduction and increases the margin over the Base Case. Due to the nature of the feed and the limitations imposed by the asphaltene content of the feed to the HCU, the staged hydroprocessing option—while providing a technically higher distillate yield—resulted in lower overall economic savings due to lower conversion from the technically maximum achievable over the hydrocracking section and using distillate to blend off excess asphaltene residue into a small amount of fuel oil. The overall CAPEX reduction was also not significant on account of a very tough feed to the hydrocracking section.

Therefore, the cumulative effect of feed optimization, the rationalization of scope, and an economic optimization of the units and utilities have resulted in a 22% CAPEX reduction in the entire project, with about 15% cost reduction across the residue conversion section of the HCU, making the residue upgrader techno-economically attractive. While the HCU on its own produces a lower distillate yield, the overall white oil production across the refinery for the optimized feed cases reinforces the concept that individual unit product distillate maximization (albeit the target product) need not result in a global overall complex economic maximum within the constraints imposed. At the time of this publication, the project was in the engineering phase.

NOTES

a Honeywell UOP’s Unicracking™ process

b Honeywell UOP’s Merox™ process

C Honeywell UOP’s Unity™ hydrocracking catalysts

REFERENCES

1 Ladkat, K. J. De Ren and K. Kashibhatia, “Improve energy efficiency of your hydrocracker unit,” ptq, Q3 2023.

2 AIChE, “Identification of polynuclear aromatic types affecting hydrocracker performance,” AIChE Annual Meeting Symposium on Recent Advances in Hydrocracking, San Francisco, California, November 1989.

ABOUT THE AUTHORS

VINOD RAMASESHAN is a Senior Engineering Consultant at Saudi Aramco, specializing in commissioning, operating and design optimization of hydroprocessing (hydrotreating & hydrocracking) units. He is a charted engineer with more than 30 yr of experience in the refining industry and has been granted 14 U.S. patents. He earned an MS degree in chemical engineering from Indian Institute of Technology, Mumbai, India.

STEPHEN GAJADHAR is a Facilities Planning Specialist at Saudi Aramco, leading techno-economic feasibility studies and conceptual engineering of refining and chemicals projects. He is a chartered chemical engineer with 26 yr of experience in the oil and gas industry. He earned Bch and MS degrees in engineering from the University of the West Indies, St. Augustine, Trinidad & Tobago.

ABDULAZIZ A. GHABBANI is a Hydrocracking Process Engineer at Saudi Aramco, working at the RTR. He has 11 yr of experience at the refinery, covering multiple engineering, operations, production planning and economics functions. He earned a Bch degree in chemical engineering from the University of Nottingham, UK.

HASSAN A. ABDULAL is a Facilities Planning Engineer at Saudi Aramco, specializing in feasibility studies and early engineering of refining and chemicals projects. He has 8 yr of experience in the refinery and petrochemicals industries. He earned a BSc in chemical engineering from the University of Colorado, Boulder, U.S.A

MAHENDRA BALODIA is a Project Development Manager at Honeywell UOP, specializing in hydrocracking, aromatics and bottom-of-the-barrel upgrading technologies. He has more than 20 yr of experience in the industry and has held various positions in engineering, technology licensing and catalyst businesses. He earned an MS degree in computer-aided process plant design from IIT Roorkee, India.

MASSIMO SANGALLI is a Lead Research Engineer at Honeywell UOP, specializing in hydroprocessing and refining conversion technologies. He has more than 25 yr of experience in the industry in various functions. He earned a PhD in chemical engineering from the University of Notre Dame, USA.

SIMMI SOOD is the Senior Business Leader for UOP hydroprocessing, FCC, alkylation, treating and heavy oils technologies. She has more than 26 yr of experience in the oil and gas industry. She is the author of two U.S. patents. She earned a Bch degree in chemical engineering from the Indian Institute of Technology, Kharagpur, India.

NEERAJ TIWARI is a Principal Hydroprocessing/Renewables Process Specialist at Honeywell UOP, specializing in the design of Ecofining™, heavy oil, hydrotreating and HCUs. He has 19 yr of experience in the refining and petrochemical industry and been granted 7 U.S. patents. He earned an MS degree in chemical engineering from the Institute of Chemical Technology, Mumbai, India.

Comments