2020 AFPM Summit: Seven imperatives for modern inventory management solutions

Seven imperatives for modern inventory management solutions

N. RAMESH MURUGAN, Honeywell Process Solutions

Today’s terminal operators are facing several challenges related to the profitability of their bulk terminal, petrochemical and oil field storage sites.

First, they are under pressure to increase margins by using all available tank capacity and shutting down any unused terminals. At the same time, they are trying to maximize throughput and performance by optimizing related activities, such as allocation, planning and scheduling.

Second, they must ensure they meet the latest American Petroleum Institute (API) and American Society for Testing and Materials (ASTM) metrology regulations, and that all reporting related to custody transfer, accounting and duties complies with specific formatting and frequency requirements. This is a full-time job that requires deep regulatory knowledge and the capability to keep pace with constant changes in the law.

Operators are also looking for ways to speed up and simplify the all-consuming reconciliation process to free up vital bookkeeping staff to perform other high-value activities. To do this, they must be able to automate longstanding manual processes and reduce administration by integrating related data from other enterprise systems such as safety, CCTV, and fire and gas into reporting and scheduling functions.

Going beyond traditional techniques. To overcome these challenges, terminal operators are looking for a new breed of inventory solution that goes beyond the capabilities of traditional management applications and uses the latest tank gauging measurement techniques.

Why tank gauging? Because it provides the data accuracy required for the effective management of inventory control, custody transfer, oil movement, and operations, leak control and reconciliation functions; in turn, this helps reduce inventory uncertainties, minimize product losses and drive terminal efficiency.

Beyond the use of tank gauging, what qualities are terminal operators looking for in modern inventory management solutions? Seven important ones qualities, or a “terminal operator’s wish list,” are discussed here.

- Improving operator efficiency—To make the best use of resources, terminal operators must take a more integrated approach to inventory management, which has been traditionally siloed from the rest of the business. This can be achieved by taking a platform-based approach in which relevant data from across the enterprise is consolidated into a single, high-level view of global inventory operations. With complete, real-time data at their fingertips, operators can make faster, more-informed decisions. Meanwhile, automating legacy, manual processes can free bookkeeping staff from time-consuming administration to focus on higher-value activities, while smart productivity features, such as the capability to embed notes for shift changeovers and to color-code information for better visibility, can lead to improved efficiency, safety and compliance.

- Optimizing assets and process—By using real-time data related to terminal inventory and capacity, operators can constantly benchmark their performance against industry standards and make ongoing adjustments to boost operational efficiency and throughput. Meanwhile, they need the capability to record and store data, such as alarms, acknowledgments and individual tank information, for future review and traceability.

- Reducing administration—The availability of complete, accurate, real-time data can help operators plan more effectively, thereby increasing turnaround time and throughput while reducing overall administration. Additionally, the ability to automate and customize reports for regulators, customers and internal stakeholders can significantly reduce the burden of paperwork.

- Lowering installation costs—Integrating an inventory management solution with other enterprise platforms and applications can help to reduce hardware and software footprint; this, in turn, helps lower ongoing installation and maintenance costs.

- Increasing accuracy—The foundation for any modern inventory management solution is precise, reliable and complete data. The capability to easily visualize, analyze and share that data in different formats can reduce inventory uncertainty, maximize capacity, and drive operational and environmental safety.

- Bringing the plant together—By taking a platform-based rather than an application-based approach to inventory management, terminal operators can remove inefficient, legacy silos and bring disparate data from multi-site operations together for the first time.

- Robust safety and security—To protect sensitive data from constantly evolving external and internal threats, any modern inventory management solution must be architected from the ground up for cybersecurity and incorporate advanced safeguards, such as tamper-proof audit trails.

Takeaway. Pressure on margins, regulatory demands and skills shortages are all creating a challenging environment for terminal operators who need accurate data to manage their bulk liquid inventory and support decisions to improve performance and drive down costs.

As we have seen, modern inventory management solutions must cater to a wide spectrum of user needs and requirements. Some offerings, such as Honeywell’s ENTIS inventory system, do just that: help terminal operators reduce inventory uncertainties, increase efficiency and minimize product losses.

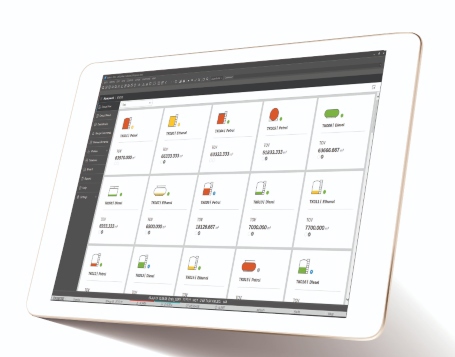

Exploring the ENTIS inventory system. With more than 2,000 installations in distribution and bulk liquids terminals worldwide, Honeywell’s ENTIS inventory system (FIG. 1) is one of the most trusted inventory management solutions on the market.

FIG. 1. Honeywell’s ENTIS inventory system helps terminal operators reduce inventory uncertainties, increase efficiency and minimize product losses.

Built on Honeywell's proven Experion® platform, ENTIS provides a single, powerful, enterprise-wide system for inventory management, integrating data from multiple sites plus related sources, such as video surveillance, and fire and gas systems.

The ENTIS Remote solution allows customers to maintain full terminal production with minimal onsite staff by augmenting local control system with remote operations capabilities. Utilize available resources from any location to maintain operations and business continuity through a range of challenging scenarios.

ENTIS also provides users with industry-leading Honeywell cybersecurity protection, the ability to automate processes at scale and seamless compatibility with the Honeywell ENRAF portfolio of reliable, versatile and accurate servo tank gauges.

Learn more at www.hwll.co/ENTIS

N. RAMESH MURUGAN is the Offering Manager—PMC Terminals, for Honeywell Process Solutions. He is responsible for product management of PMC Terminals Software and Fusion4 Loading Portfolio. Mr. Murugan has more than 20 yr of experience in the process plant and industrial automation domain. He has worked for the last 13 yr at Honeywell on different product lines of ENRAF and Advanced Solutions. Prior to Honeywell, he was with Chevron Oronite Indian Additives and was involved in process engineering and technology transfer. He holds an MS degree in petroleum refining and petrochemicals from Anna University and an Executive General Management Certification from the Indian Institute of Management (IIM) in Bangalore.

Comments