Digital Exclusive (sponsored): Improve efficiency via centralized data and advanced collaboration

The ability to access accurate information is essential for making informed decisions within the world of industrial operations. In the oil and gas industry, digitalization can help monitor operations and make more informed decisions. The rise of digitalization in the industry is a paradigm shift towards more sustainable and profitable operations.

This article will detail how companies can use digital solutions to transform their engineering and data management by seamlessly integrating real-time data across the entire asset lifecycle, enabling faster, more accurate decision-making to improve efficiency, increase safety, minimize downtime and enhance profitability.

Revolutionizing integration: The role of HxGN SDx2. In the oil and gas sector, integrating the right people with the right digital tools is critical for navigating contemporary challenges and harnessing opportunities. As the industry evolves, the integration of advanced technologies empowers the workforce, enabling them to perform tasks with greater accuracy and speed, thereby driving profitability.

Hexagon’s digital backbone, made possible by HxGN SDx2, serves as a central platform for smooth data sharing between HxGN SDx2’s core applications, third-party vendor systems and customer-developed tools. This robust integration allows diverse teams (e.g., engineering, procurement, materials management, logistics, maintenance) to collaborate efficiently and respond more swiftly to changes or urgent requirements.

By bringing these diverse disciplines into a unified ecosystem, organizations can streamline workflows and eliminate information silos that hinder progress. This integrated environment enhances operational efficiency and enables all stakeholders—internal and external—seamless access to accurate, real-time information, supporting more informed decision-making.

Enhancing collaboration during design. Intergraph Smart Design Solutions are transforming the landscape of information exchange across multiple engineering disciplines, delivering near real-time collaboration via intuitive digital workflows. These solutions, which include Intergraph Smart P&ID, Intergraph Smart Instrumentation and Intergraph Smart Electrical, continuously share information, documents and drawings directly with the digital backbone.

Previously, users had to manually share information. Now, while manual sharing remains an option, the new integration processes are highly automated and continuous. This accelerates communication across disciplines, reducing schedules and minimizing churn.

HxGN SDx2 introduced a leaner database architecture, upgrading automation, optimizing performance and reducing manual input errors. Its user interface has also been meticulously redesigned to be even more user-friendly, simplifying the processes of searching, managing changes and producing comprehensive work packages. This synergy improves users’ experiences and facilitates faster onboarding for new users, enabling teams to adapt quicker to evolving project demands. By enhancing these core functions, organizations can foster a culture of continuous improvement and agility to remain competitive in rapidly changing markets.

Maintenance and operations use case. In an active facility, a process technician may need to inspect inline devices within a specific pipe run due to concerns like mechanical wear or corrosion. Traditionally, this requires the labor-intensive task of gathering all relevant drawings, reports and datasheets—a time-consuming process prone to error.

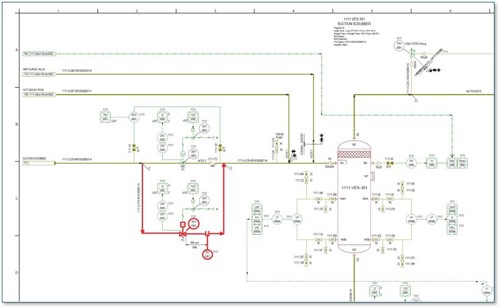

With Intergraph Smart P&ID, the technician can generate detailed reports and drawings focused solely on devices relevant to the maintenance activity, significantly enhancing preparation efficiency. For instance, Intergraph Smart P&ID enables users to filter content by various device attributes (e.g., class, naming conventions, pressure ratings, temperature limits, motor horsepower), providing a level of specificity unattainable with legacy methods (see Figure 1). This tailored output directly supports maintenance tasks by delivering precise, customized information, saving time and improving the accuracy of inspections and repairs.

Using HxGN SDx2, technicians can access these filtered reports and drawings without needing direct access to Intergraph Smart P&ID. This more streamlined workflow enhances productivity, while the ability to access real-time information from any device (e.g., desktop, tablet, mobile) allows technicians to make quick, more informed decisions onsite, ultimately boosting accuracy and reducing operational downtime.

Design and engineering use case. Long before P&ID drawings are formally issued for design or construction, information within them becomes relevant for adjoining engineering disciplines—even as the data remains in flux. Intergraph Smart P&ID’s ability to share data and drawings through the digital backbone enables key information (e.g., equipment list, piping line list, instrument tags, electrical consumers) to be continuously provided to other disciplines.

These design parties will receive notifications of incoming changes to HxGN SDx2 via a share dashboard, allowing them to more readily perform comparisons with their own data, documents and drawings. Given the commonality of compressed project schedules, even approval-level content is highly relevant for other parties involved in project execution.

Diving deeper, it’s customary for portions of a P&ID drawing to mature at different rates, as process simulation, stream data and associated engineering efforts evolve. Certified vendor information may not always arrive promptly, delaying the overall issuance of construction-level drawings. With Intergraph Smart P&ID, individual objects can be assigned a particular data quality, employing multiple status fields to define if a vessel, valve or motor is at a preliminary quality, issued for design, procured, assigned to a system and sub-system, installed or commissioned.

Staff in such roles as review, checking, procurement, materials management and construction logistics will appreciate the capability to pull drawings and reports, even when portions of the drawings aren’t fully mature. They will be better equipped to forecast their own efforts, gaining clarity on what equipment and structures are “ready to go” and which items require further details.

Configurable workflows for document releases. It is notable that HxGN SDx2—when it comes to official document releases—offers configurable workflows to notify various audiences of changes specific to their personas. For instance, a release may only be internal in scope (sometimes called a “squad check”), seeking input only from peers in engineering and design, without releasing the document to a larger audience (including procurement and construction).

The benefits of HxGN SDx2 and Intergraph Smart Design Solutions. The integration of HxGN SDx2 with Intergraph Smart Design Solutions is a game-changer that optimizes collaboration between engineering, procurement, construction and maintenance teams. The seamless data sharing capabilities, coupled with automated workflows and real-time updates, significantly improve overall efficiency and empower all stakeholders to make quicker, better, more informed decisions. This dynamic duo not only enhances individual workflows while contributing to a more interconnected and responsive organizational structure. By embracing this innovative integration, organizations improve performance, drive operational excellence and better position themselves for success in an increasingly competitive landscape.

For more information about HxGN SDx2 and how it can benefit your organization, contact Hexagon today and visit: HxGN SDx2 | Hexagon

About Hexagon. Hexagon is a global leader in digital reality solutions, combining sensor, software and autonomous technologies.

Hexagon’s Asset Lifecycle Intelligence division helps clients design, construct and operate more profitable, safe and sustainable industrial facilities. We empower customers to unlock data, accelerate industrial project modernization and digital maturity, increase productivity, and move the sustainability needle.

Hexagon has approximately 24,500 employees in 50 countries, and net sales of approximately €5.4 B. Learn more at www.hexagon.com, and follow us @HexagonAB.

Comments