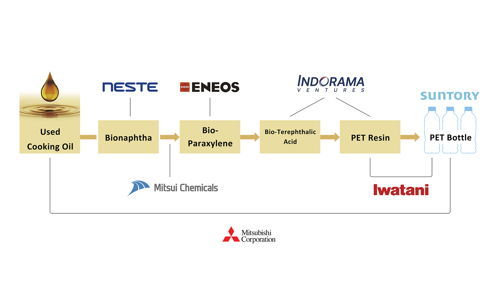

Consortium to launch world's first commercialized PET bottle using bio-paraxylene

Indorama Ventures Public Company Limited, as part of a supply chain collaboration with Suntory, ENEOS Corporation, Mitsubishi Corporation, Iwatani and Neste, will launch the world’s first1 bio-PET bottle for commercial scale, made from ISCC+ certified bio-paraxylene2 This collaboration marks a significant milestone in the journey toward sustainable packaging, introducing PET bottles derived from used cooking oil. PET bottles made from this technology can significantly reduce CO2 emissions of products.

From November onwards, the Suntory Group will successively introduce these bio-PET bottles for selected products in Japan. The collaboration will see the launch of approximately 45 million PET bottles for beverages made with this innovative material3 with further introduction for Suntory products to be considered in the future.

By combining the expertise and resources of industry leaders across the value chain, this initiative underscores the power of collaboration in addressing global sustainability challenges.

Mr. Yash Lohia, Executive President Petchem Special Projects, and Chairman of the ESG Council of Indorama Ventures, stated, “This exciting collaboration reflects the shared vision and responsibility of all partners involved to contribute to a more sustainable future. We are proud to work alongside industry leaders in this pioneering effort, which not only brings new possibilities to the packaging industry but also reinforces the importance of collaboration in driving meaningful change. And we are excited to see the fruits of the collaboration on the shelves soon as high-quality Suntory products."

Role of each stakeholder in this project

|

Mitsubishi Corporation |

Manage entire supply chain |

|

Neste |

Produce bio-naphtha from used cooking oil in ISCC+ certified plant |

|

Mitsui Chemicals, Inc. |

Produce intermediate material of bio-paraxylene using bio-naphtha in ISCC+ certified plant |

|

ENEOS Corporation |

Produce bio-paraxylene from intermediate material in ISCC+ certified plant using mass balance approach*2 |

|

Indorama Ventures |

Produce PET resin by reacting MEG with PTA (TPA) produced with bio-paraxylene in ISSC+ certified plants |

|

Iwatani Corporation |

Manage operation from production to delivery of PET resin |

|

Suntory Group |

Form PET resin into PET bottles for its products |

This launch represents a major step forward in reducing the environmental footprint of PET production. The mass balance approach applied throughout the production process ensures that the bio-based materials are transparently and effectively integrated into the PET bottles.

As a partner in this initiative, Indorama Ventures remains committed to fostering a circular economy for the future of packaging through various avenues. The production of bio-PET resin aligns with Indorama Ventures’ long-term sustainability strategy and strengthens its commitment to providing environmentally responsible solutions to its customers.

NOTES

1 As of October 28, 2024. Based on research by ENEOS Corporation and Mitsubishi Corporation

2 Mass balance approach applied. Under the mass balance approach, for a product manufactured by mixing a material that has a specific characteristic with those without that characteristic, the characteristic can be allocated to a part of the output of the product in proportion to the amount of the material with the characteristic used in the production process. The mass balance approach has been ISCC+ certified

3 280ml and 285ml PET Bottles.

Related News

- Applied Computing and KBR to launch AI-based solution for optimized ammonia production

- Technip Energies awarded two large contracts by BPCL for new units at Bina and Mumbai refineries in India

- ADNOC and TAQA announce 27-yr utilities agreement with TA’ZIZ, enabling world-scale chemicals production at Ruwais

Comments