EIA: U.S. refining capacity increased in 2023 with expansions and existing facilities

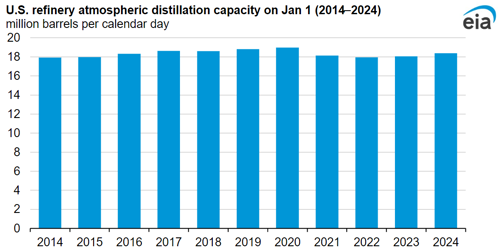

U.S. refining capacity increased this year for the second time since the COVID-19 pandemic, according to the U.S. EIA’s annual Refinery Capacity Report. U.S. operable atmospheric crude oil distillation capacity, the primary measure of refinery capacity, totaled 18.4 MMbpd at the start of 2024, a 2% increase compared with the start of 2023.

Calendar day capacity represents the operator’s estimate of the input volume that a distillation unit can process in a 24-hour period under usual operating conditions, considering the effects of both planned and unplanned maintenance. The calendar day capacity companies report to EIA may differ from the headline capacity numbers that companies use elsewhere because of differences in estimation methodology.

Most additions to U.S. refining capacity in the last 10 years have been expansions to existing facilities, the reactivation of previously decommissioned units, or the addition of relatively small facilities. Reductions in refinery capacity largely reflect facilities that were decommissioned due to damage, as well as facilities that transitioned from petroleum refining to renewable fuels processing.

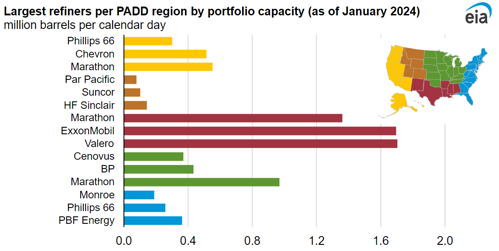

How did U.S. refining change in 2023? In 2024, the three largest refiners in the U.S.—Marathon, Valero, and ExxonMobil—all reported increases in capacity compared with 2023. Phillips 66, the fourth-largest U.S. refiner, reduced capacity last year. PBF Energy overtook Chevron to become the fifth-largest U.S. refiner by portfolio capacity.

The increase in capacity in the beginning of 2024 primarily reflects increases in capacity at existing facilities. ExxonMobil completed a major refinery capacity addition in Beaumont, Texas, in March 2023, boosting the facility’s total crude oil distillation capacity from 369,000 bpd to 609,000 bpd.

Valero also completed an expansion project at its Port Arthur refinery, increasing its distillation capacity by 25,000 bpd to 360,000 bpd. The increase in distillation capacity came alongside a 50,000-b/cd increase in the refinery’s coking capacity, increasing its ability to process heavier crude oil grades into more high value products, such as gasoline or diesel fuel.

Finally, Marathon’s Galveston Bay refinery increased its capacity 6% to 631,000 bpd. The additional capacity means the Galveston Bay refinery has overtaken Motiva’s 626,000- bpd Port Arthur refinery as the largest refinery in the United States in terms of atmospheric distillation capacity.

Three major refining transactions took place in 2023. In February 2023, Canadian refiner Cenovus acquired the 150,800- bpd Toledo refinery in Ohio from BP-Husky Refining. In June, ExxonMobil sold its 61,500- bpd refinery in Billings, Montana, to Par Montana—a portfolio company of Par Pacific. Finally, in September, Oneok acquired Magellan Midstream Partners, including Magellan’s 42,500- bpd condensate splitter in Corpus Christi, Texas, as well as the company’s network of petroleum product and natural gas liquid pipeline infrastructure.

This year’s Refinery Capacity Report includes 132 operable refineries, compared with 129 at the beginning of 2023. One new facility is included in the report: the reactivated 32,000-bpd CPI Operations facility in Paulsboro, New Jersey, accounting for 10% of the additional distillation capacity last year.

Has U.S. refining capacity changed more recently? The 2024 Refinery Capacity Report only reflects changes in U.S. refining capacity in effect as of January 1, 2024. Phillips 66 formally ended petroleum refining operations at its Rodeo refinery in February 2024. The facility previously reported a capacity of 120,200 bpd in 2023, but it has been scaling back operations and only reported a capacity of 58,200 bpd as of January 1, 2024. This year-on-year reduction in capacity does not reflect the end of petroleum refining operations the following month, although the loss of the remaining capacity is reflected in the monthly refinery capacity and utilization data, beginning in March 2024. The facility has been transitioning to the production of biofuels, particularly renewable diesel.

LyondellBasell previously said it would close its 263,776-b/cd refinery in Houston by the end of 2023, but it later announced it was delaying the closure. The firm currently expects to close the refinery by the end of the first quarter in 2025. Unless the closure is completed by January 1, 2025, the closure will not be reflected in next year’s Refinery Capacity Report.

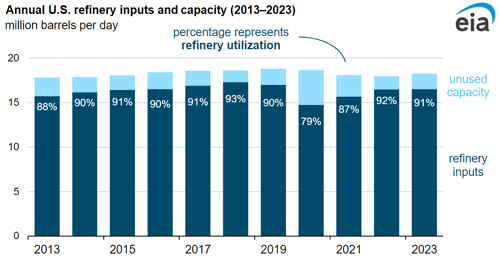

What were refinery operating conditions in 2023? Annual refinery utilization decreased by one percentage point to 91% in 2023 because refinery capacity increases exceeded the increase in annual inputs.

Utilization decreases when refineries go offline for necessary maintenance, unforeseen disruptions, or safety considerations. Running at 100% utilization of capacity for a sustained period is extremely difficult. Annual refinery utilization over the last 10 years (2014–23) has averaged about 89%.

Utilization has been relatively high the last two years as refiners increased operations in response to high petroleum product prices, producing greater quantities of petroleum products such as motor gasoline and diesel. High prices reflected reduced global refinery capacity and changing global petroleum trade flows. However, refining capacity additions last year gradually contributed to decreasing product prices relative to 2022.

How did secondary unit capacity change in 2023? U.S. thermal cracking (or coking) capacity increased 1.9% in 2023. Catalytic cracking capacity and hydrocracking capacity each increased by 0.4% from January 2023. Catalytic cracking, hydrocracking, and coking capacity all help refineries to reduce their yields of low-value residual products and increase their yields of high value products such as motor gasoline, diesel, and jet fuel.

Desulfurization capacity, which is used to bring gasoline and diesel fuel into compliance with on-road emissions standards, also increased by 1.2%, which reflects the inclusion of the Enterprise and Targa Mont Belvieu facilities. Alkylation capacity, which is used to produce higher octane grades of gasoline, also increased by 1.2%, while isomerization capacity, which is also used to produce certain gasoline blend components, increased by 1.5%. Production capacity of on-site hydrogen increased by 1.3%. Aromatics production capacity increased by 19.8%.

Related News

- Honeywell collaborates with SAF One and Tata Projects to enable sustainable aviation fuel production

- CF Industries, POET launch low-carbon fertilizer pilot to cut ethanol production carbon intensity

- Technip Energies awarded two large contracts by BPCL for new units at Bina and Mumbai refineries in India

Comments