Digital Exclusive: Cloning design provides plug-and-play approach for carbon capture

HOPKINS, Burns & McDonnell, Kansas City, Missouri

Carbon capture has the potential to significantly decarbonize emissions from industrial facilities. One of the first types of processes to utilize carbon capture and sequestration (CCS) was ethanol production.

Ethanol is a component in most gasoline blends. As a renewable fuel produced from corn or other biomass, ethanol reduces emissions during combustion and helps refiners meet federal emissions regulations and important sustainability goals.

However, the multi-stage ethanol production process—everything from milling corn to liquefaction, cooking and fermentation—can emit significant volumes of carbon dioxide (CO2). Although current production techniques for corn-based ethanol blends can reduce lifecycle emissions by more than 40% over unblended gasoline, sequestering the CO2 that is typically emitted by the ethanol process represents an opportunity to enhance environmental benefits.

As fuel producers look for ways to reduce carbon intensity of fuel production and improve overall process design, more ethanol producers are evaluating CCS opportunities. The approach to sequestrating CO2 from ethanol operations provides the purview of how large-scale sequestration can be implemented across the process industries.

Momentum for carbon reduction building worldwide. Across the world, momentum is building for carbon reduction. Government policy continues to strengthen the potential of carbon capture, utilization and storage (CCUS) applications to meet net-zero goals:

- In the U.S., carbon capture projects may also be eligible for certain tax credits for clean energy projects under the 2022 federal Inflation Reduction Act.

- In Canada, the 2021 Net-Zero Emissions Accountability Act establishes a carbon pricing regime that is creating further momentum for carbon capture technologies.

- In the European Union (EU), energy and climate targets set for 2030 are heavily weighted toward CCS technologies, including an EU framework to standardize and certify carbon removal volumes.

- The United Arab Emirates and Saudi Arabia have net-zero target by 2050 and 2060, respectively.

- Recent policy, legal and regulatory developments across the Asia-Pacific region highlight the increasing focus of government and industry on CCUS technology.

Carbon capture clones. Within the heavy industrial sector, repeatable design and standardization of equipment and components is the order of the day. Applying these principles to a carbon capture system can help ethanol producers—along with other industries—to achieve savings and operations efficiencies.

Though carbon capture can be a complex process, multiple proven pre- and post-combustion process technologies make it feasible to capture CO2 emissions. Applying this process technology in a consistent manner results in a standardized inside battery limits (ISBL) design which can be replicated or cloned, while the outside battery limits (OSBL) design can be customized for each location.

Plug-and-play at multiple sites. For one large ethanol producer, the author’s company began with the concept of developing a carbon capture unit that standardizes design specifications for compressors, dehydration skids, auxiliary equipment and pipe spools. These cloned designs are repeated as blocks to be dropped in as carbon capture units at multiple ethanol processing facilities. The carbon capture units include multi-stage compressors that drive the gas stream to a triethylene glycol (TEG) dehydration skid. After the water is separated from the gas stream, the water is then returned to the ethanol or waste treatment facility, while the CO2 is pumped into a pipeline.

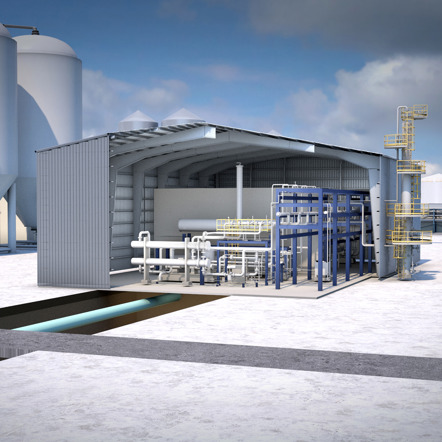

FIG. 1. Early rendering of a multisite ethanol carbon capture project for a North American refiner. The author’s company developed a carbon capture unit that standardizes design specifications for compressors, dehydration skids and auxiliary equipment.

The CO2 capture equipment is housed in a building. The layout of the equipment is cloned, and the building can be rotated to any angle needed to fit within the multiple site plots. The equipment is engineered to uniform specifications within each building, regardless of the site layout. Some custom, site-specific design will be required for OSBL aspects of the project and may include geotech surveys, civil engineering and certain other activities to meet varying requirements of individual sites.

By modularizing as many components as possible, constructability in the field becomes much easier and improves with each unit installed as skilled trades and craft become much more familiar with work packages. Additionally, project quality is improved as components such as pipe racks are fabricated in controlled shop environments.

The cloning project planning and development process moves through five stages:

- Stakeholder alignment. The standardization process begins with early input from stakeholders. This step is essential as stakeholders are asked to review all possible variations before the site design phase begins. This feedback and buy-in helps mitigate late changes, which could increase project costs and push out schedules.

- Block identification. Based on feedback on which equipment and piping layouts can be standardized, engineering proceeds to an evaluation of where blocks should start and stop within the clone unit. Numbering and other identification methods for blocks and components are also developed at this stage.

- Block design and review. Based on feedback and input from project stakeholders, a locked-in block design is executed. The design plan is considered final at this stage.

- Site-specific design. All custom design is executed under this phase and may include the arrangement of blocks based on topography, geography, tie-in locations, proximity to other equipment and maintenance access. It is anticipated that each project will require some site-specific OSBL design.

- Lessons learned and process improvement. Following startup and commissioning, a review of all design, procurement and construction is completed to identify how block design processes can be improved to increase efficiencies, reduce costs and tighten schedules for later installations.

Additional cloned CCUS applications. These design concepts can be applied to a wide range of assets, from natural gas plants to compressor stations to hydrogen production facilities. Generally, any large point source of CO2 offers the potential for a cloned solution.

Natural gas processing facilities have an existing amine system in place to remove contaminants from the natural gas. These amine units produce a waste CO2 stream at high purity that can benefit from a cloned carbon capture design for the compression and sequestration of CO2.

Other higher purity sources of CO2 can be found in existing ammonia production facilities, with hydrogen production being the most carbon-intensive portion. Because the Haber-Bosch process that is utilized accounts for up to 2% of the world’s total CO2 emissions, carbon capture plants could help reduce the amount of CO2.

Benefits realized. The clone units allow different types of process facilities to minimize costs for engineering, procurement, fabrication and construction. By replicating one design many times, efficiencies ranging from sourcing of long-lead equipment and components to fabrication in controlled shop environments can drive down costs and improve lead times. Construction schedules may also be compressed as more units are installed and crews gain familiarity with installation procedures.

Comments