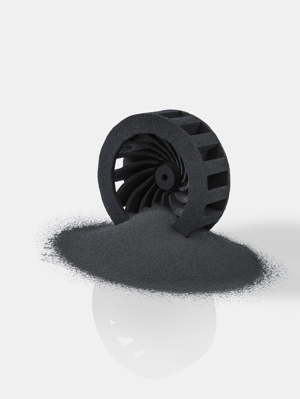

CARBOPRINT– SGL &The ExOne Company aim to make carbon ready for 3D printing market

Wiesbaden, SGL Group is continuously working on additional future growth areas for carbon and graphite material applications. One area is 3D printing of components made of carbon. 3D printing describes the building of individual layers of material into three-dimensional parts based on a digital file, without tooling or machining. SGL Group is bringing carbon and graphite components created using 3D binder jet printing technology provided by ExOne to the market under the brand name CARBOPRINT®.

Collaboration between the companies is founded in expertise from both sides: SGL Group offers knowledge on the raw material and powder preparation, as well as versatile technologies for post-processing carbon components. ExOne contributes its competences in 3D printing.

As the carbon body is initially porous after printing, SGL Group post-processing, such as polymer impregnation or silicon or metal infiltration, play a major role. These additional processes allow the adjustment of versatile material properties to the specific application.

Thanks to the basic properties of carbon, such as high chemical stability and good electrical and thermal conductivity, first trial components are being developed for testing in applications in the areas of chemical apparatus construction and environmental technology. Concrete examples include heat exchangers and components for distillation columns, as well as pump components made of siliconized 3D-printed carbon.

Comments